-

Home

- ABOUT

- PRODUCT

-

Geotechnical and road material testing instrument series

-

Rock and aggregate testing instrument series

-

Cement and concrete testing instrument series

-

Asphalt and Asphalt Mixture Testing Instrument Series

-

On site testing instrument series

-

Mechanical testing equipment series

-

Environmental Box Series

- NEWS

- INDUSTRY

-

road traffic

-

Construction and building materials

-

Hydroelectric and Water Conservancy

-

Teaching and research

-

Environment and climate

Inquiry

Contact UsIf you have any questions, please contact us immediately!- Geotechnical and road material testing instrument series

- Rock and aggregate testing instrument series

- Cement and concrete testing instrument series

- Asphalt and Asphalt Mixture Testing Instrument Series

- On site testing instrument series

- Mechanical testing equipment series

- Environmental Box Series

PRODUCT

Product Center 立即咨询 +86 538-8931996 返回

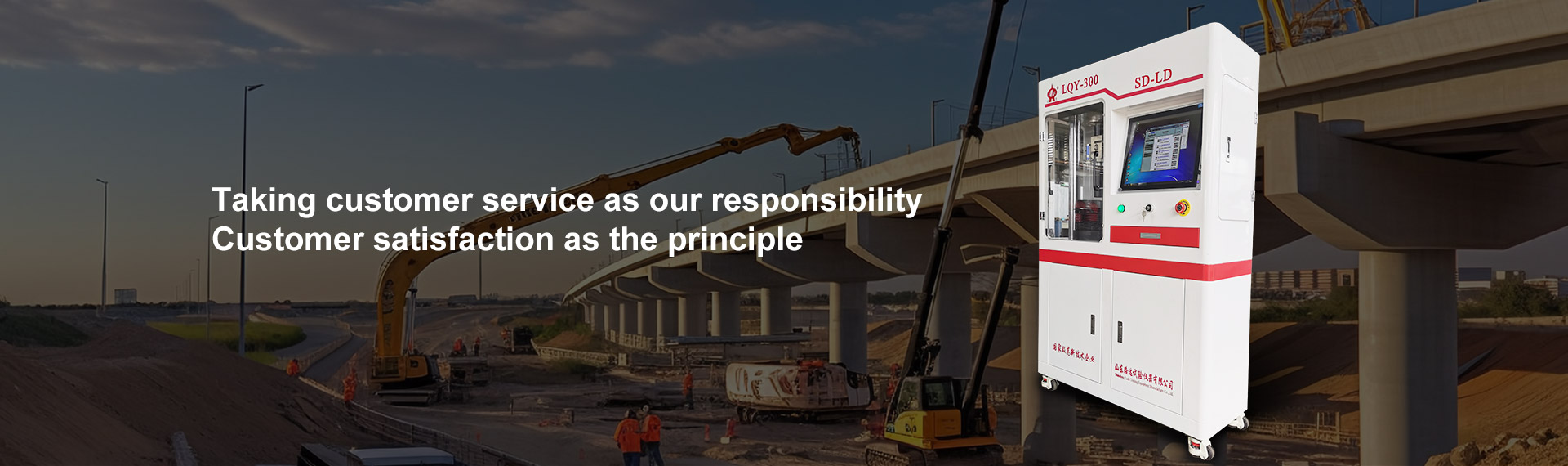

立即咨询 +86 538-8931996 返回LQY-300 Electronic pavement material strength testing machine

scope of application:The electronic pavement material strength testing machine is suitable for the axial force of inorga...微信扫码咨询

产品详情

scope of application:The electronic pavement material strength testing machine is suitable for the axial force of inorganic binder specimens under uniaxial compressive stress.

Determine the unconfined compressive strength of specimens of inorganic binder stabilized materials (including stabilized fine soil, medium soil and coarse soil).

The flexural strength of inorganic binder stabilized materials was determined, and the basic parameters were provided for the loading standard determination of the flexural strength test of inorganic binder stabilized materials. The three-point compression method was used in the test.

The bending and tensile rebound modulus of inorganic binder stabilized material under static load was measured by three-point loading method.

Performance features:

1. It is mainly composed of host compression, bending and pulling mechanism unit, automatic control system unit, computer and special software data acquisition system unit;

2. The device uses a servo or variable frequency motor to drive the cantilever's up and down movement through a transmission mechanism, enabling the loading process for testing. It employs a fully digital closed-loop control system for both control and measurement. A computer is used to dynamically display the test process and the test curve, as well as to process the data. After the test, the data can be reanalyzed and edited, ensuring that the product performance meets the required standards.

3. Function

(1) Constant load force to collect displacement and deformation;

(2) Constant displacement to collect force value and deformation, peak tracking can be measured, residual force value can be measured;

(3) Cylindrical specimens: φ150×150mm; φ100×100mm (used for compressive strength deformation splitting test);

(4) Static pressure forming test mold and bending device: specification optional.

technical parameter:

1. maximum test force: 300kN;

2. accuracy level: 0.5;

3. Test force measurement range: 0.4%~100%FS (full scale);

4. test force indication error: the indication is within ±0.5%;

5. Resolution of test force: ±1/300000 of the maximum test force, no step throughout the whole process, and the resolution remains unchanged throughout the whole process;

6. force control rate adjustment range: 0.005~5%FS/s;

7. Force control rate control accuracy: when the rate is less than 0.05%FS/s, it is within ±2% of the set value, and the rate is greater than or equal to 0.05%FS/s, within ±0.5% of the set value;

8. deformation: range 0~10mm accuracy 0.001mm;

9. constant force control range: 0.5%~100%FS;

10. Constant force control accuracy: when the set value is greater than or equal to 10%FS, it is within ±0.5% of the set value; when the set value is less than or equal to 10%F

When S is, it is within ±1% of the set value;

11. maximum travel: 200mm;

12. Maximum distance between upper and lower pressure plates: 450mm;

13. power supply: 220V/50Hz, ±10%.

Message

- Consultation Hotline

- Service Hotline:+86 538-8931996

- E-mail: tangfei88@vip.163.com

- ABOUT